Shanghai Leadgo-tech Co., LTD. Introduced a new film cutting production line from abroad for pre-cut vacuum bag film.The equipment adopts computer-aided control system with high degree of automation. According to the size of the graphic input in the computer, the film can be cut diagonally through the two-way movement of the film and the cutter, forming trapezoid or conical bag film with different shapes and sizes.

FIG. 1 Schematic diagram of pre-cut vacuum bag film

New development of pre-cut vacuum bag film can be customized according to customer request design services, to adapt to the customer's production mold, as the mold size varies in length direction, in order to reduce the membrane in the process of using the cutting, make customers more convenient operation, not only also reduced the waste and loss, saves the production cost for the customer.

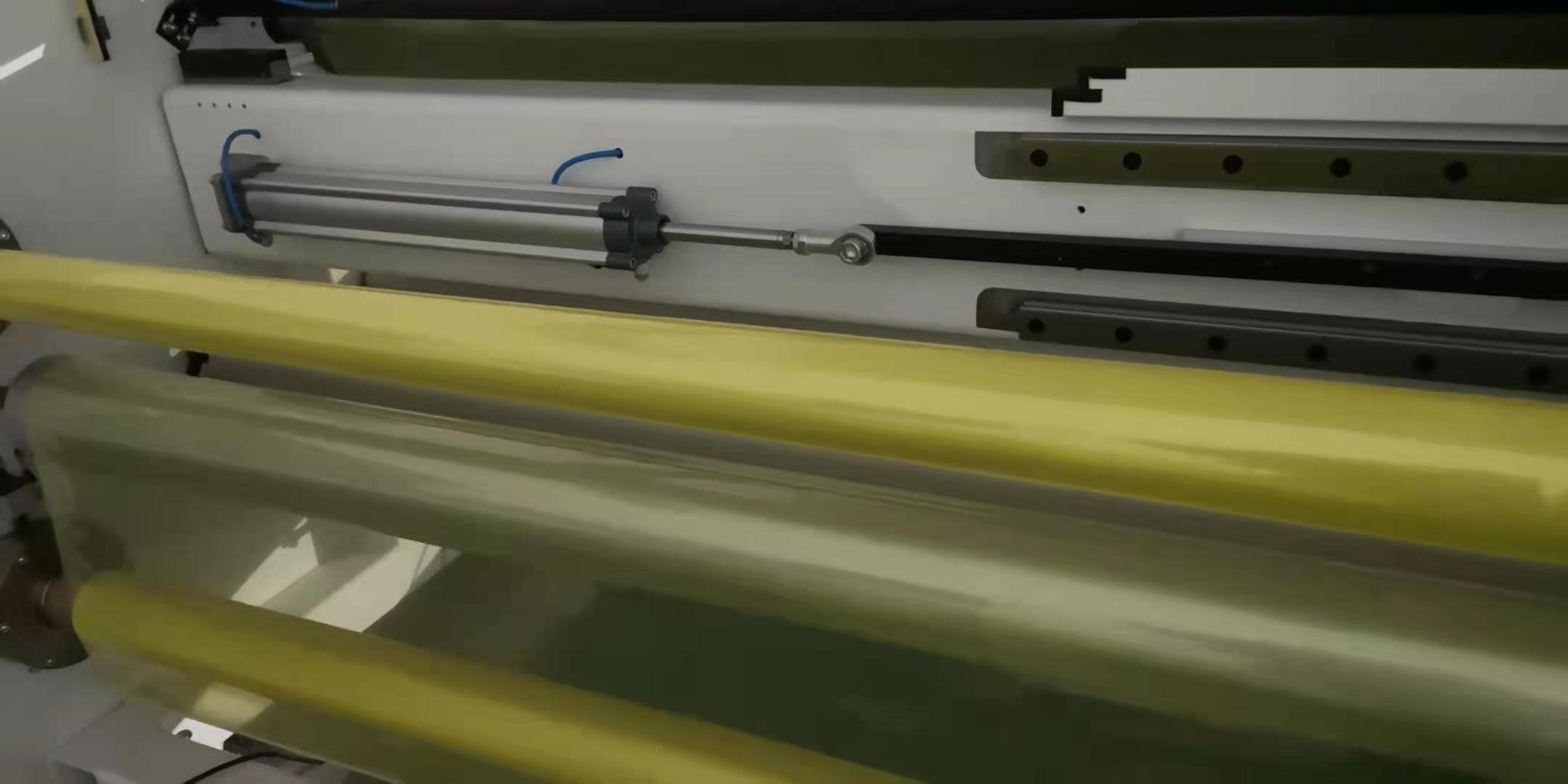

FIG. 2 Production diagram of pre-cut vacuum bag film

Table 1 Technical data of pre-cut bags

|

Model |

Thickness/um |

Maximum temperature/℃ |

The size range of the cut |

|

LVBF600Y |

50/65/75 |

150 |

4~8m |

|

LVBF165B |

55/75 |

165 |

4~8m |

|

LVBF250V |

75 |

170 |

4~8m |

The pre-cut vacuum bag film produced by our company can choose different brands and specifications according to customers' different use requirements. The pre-cut bag generally adopts LTX form.

Leadgo always pays attention to the research and development of high-performance auxiliary materials, and customers' demands are the driving force for our continuous progress. The introduction of pre-cut vacuum bag film will enrich the company's product line, provide customers with more personalized services, and solve the practical problems in composite material production to the greatest extent.